Step by Step: Repairing the Cracked Plastic Head Mount Bracket on an 8-Track Player

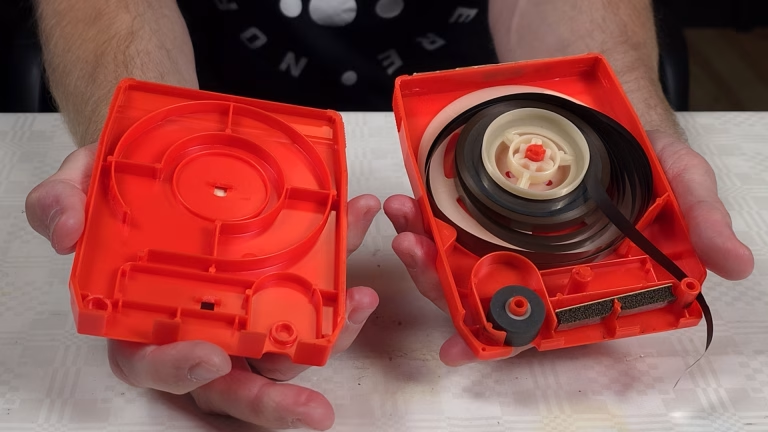

This is a thorough walkthrough of how to repair the plastic bracket that holds the sound head on 8-track players with the infamous plastic construction. In this example, we are working with a Realistic TR-169 player, but the procedure is largely the same on all players with a similar mechanism.

This process can also be used preventively – even on healthy brackets that haven’t cracked yet. Reinforcing with wire helps strengthen the bracket and reduces the risk of future damage.

Tor-Atle Kindsbekken

Procedure

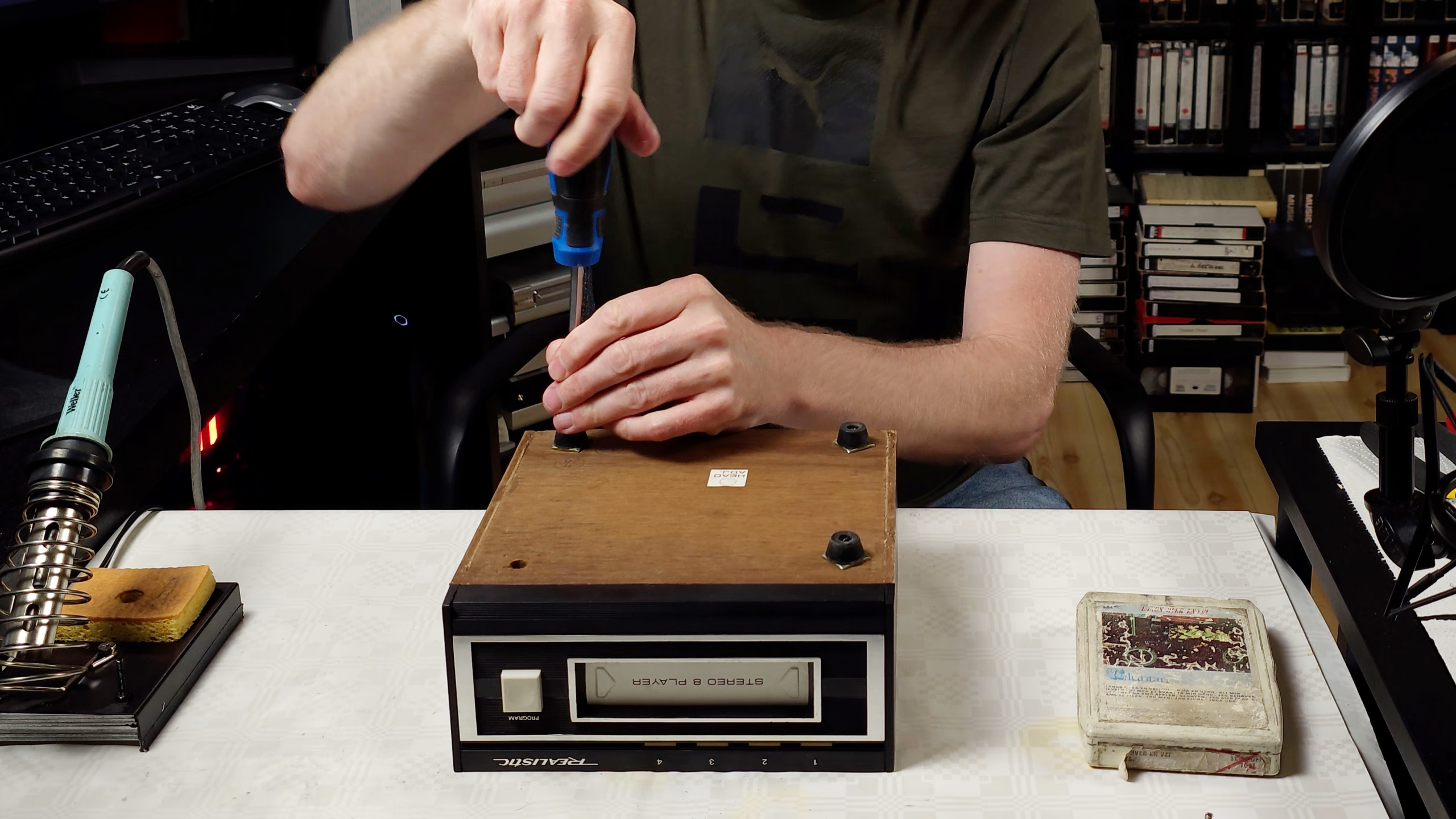

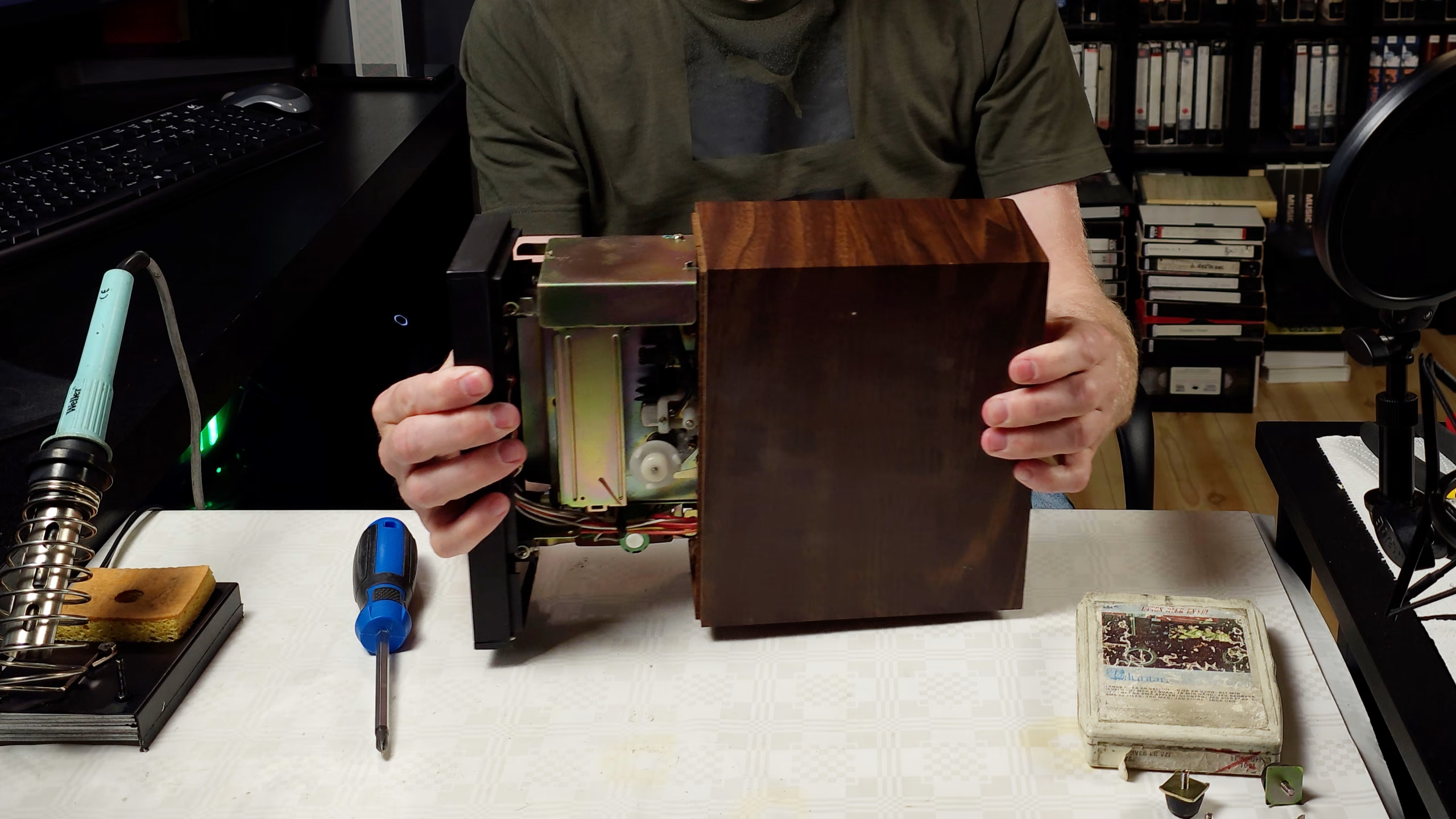

Disassembly:

- Remove the feets to open the player

- Slide off the cover by pulling the front out of the chassis.

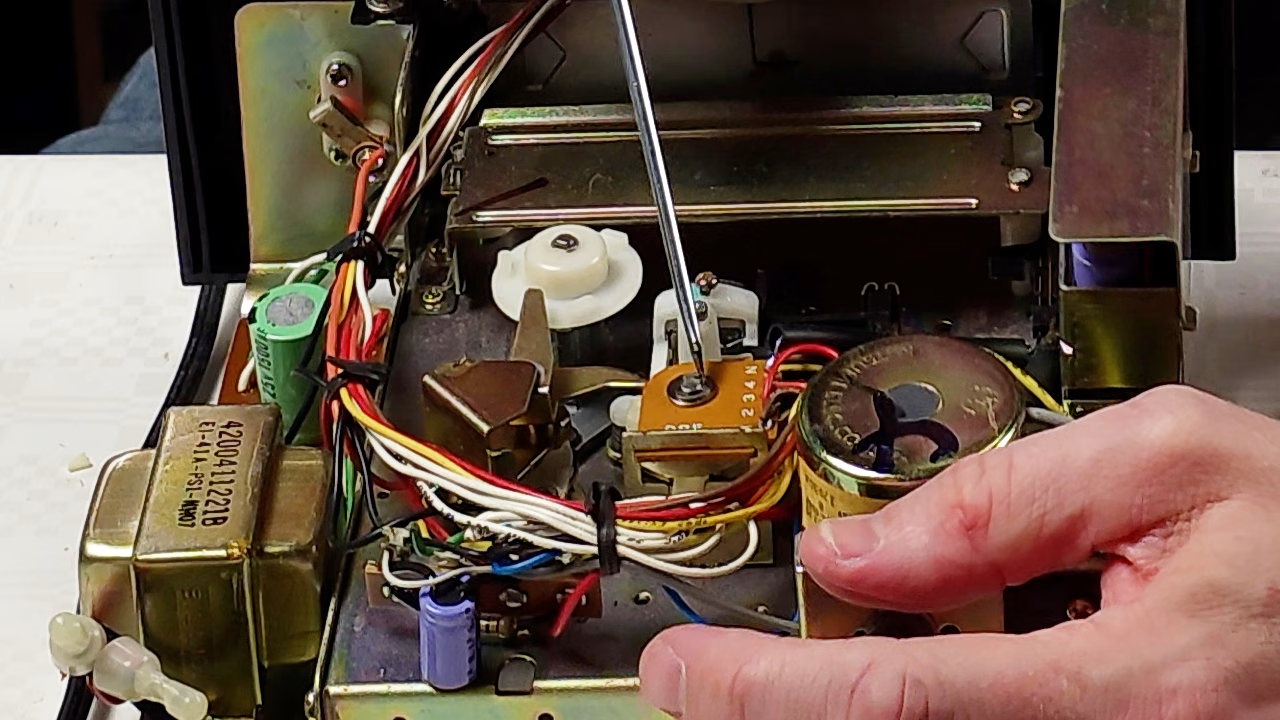

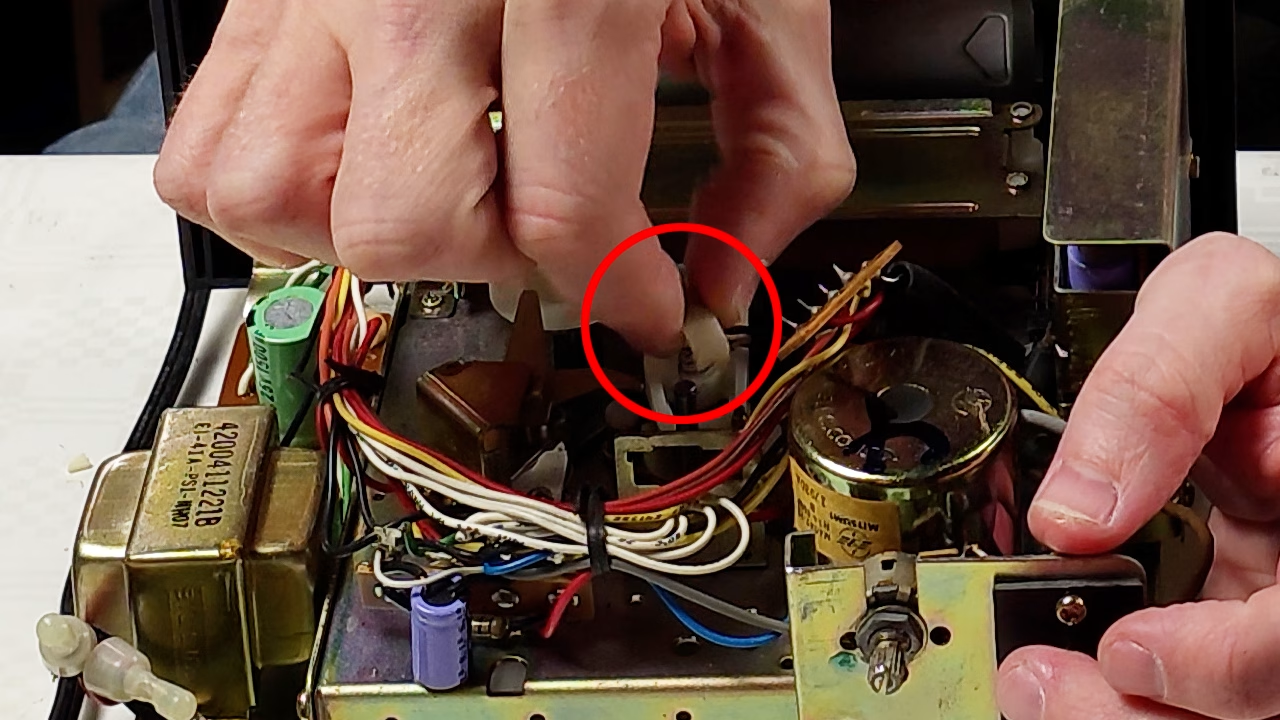

- Remove the E-clip ring and washer

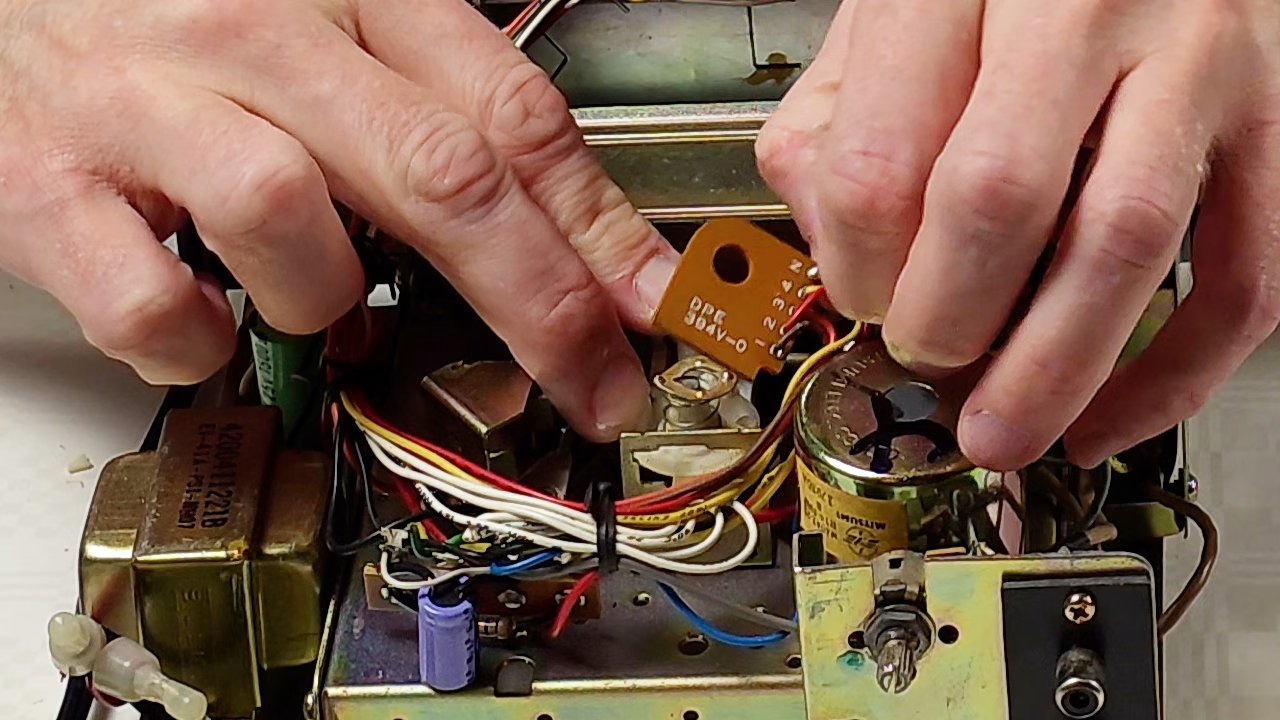

- Lift out the small brown circuit board

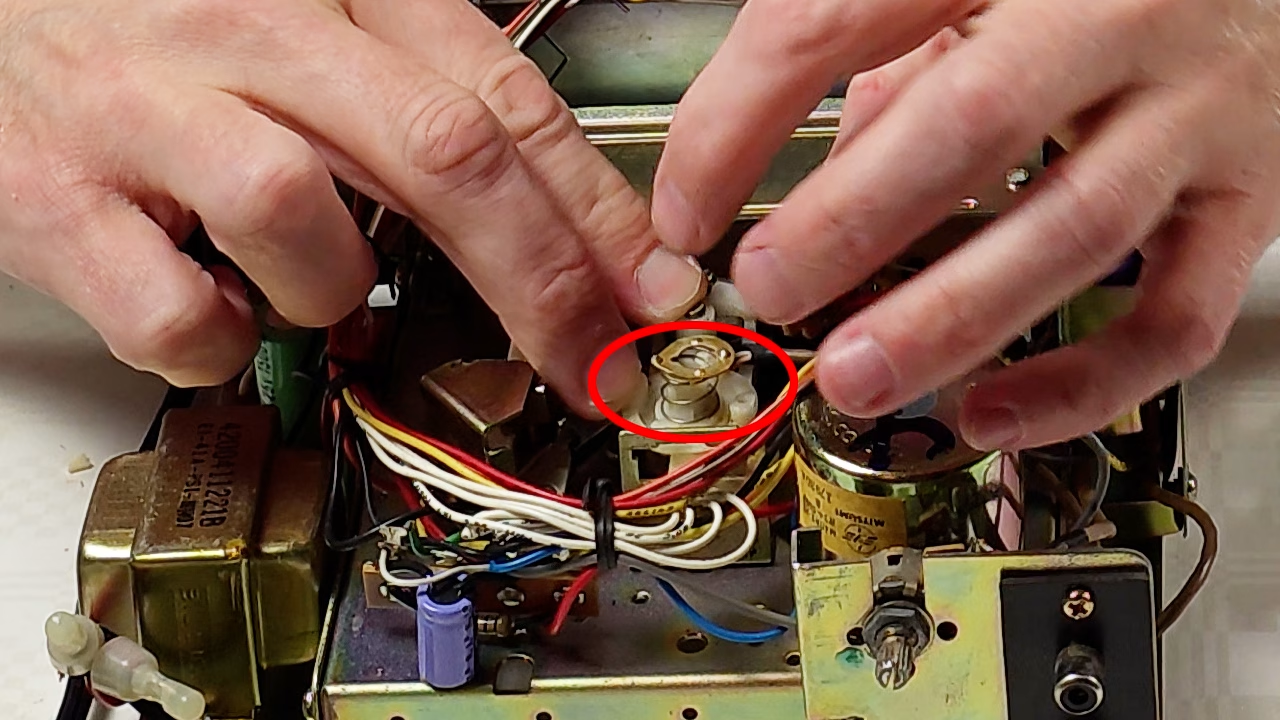

- Remove the metal ring and spring beneath it

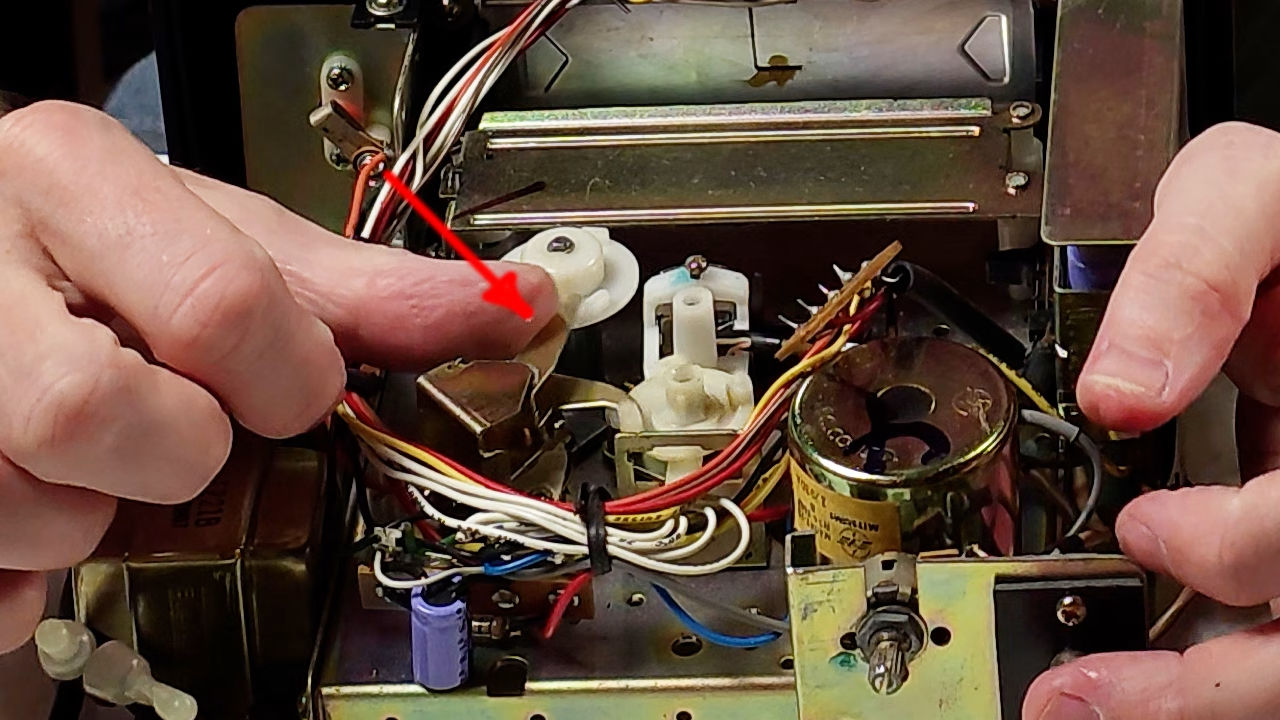

- Swipe the track change motor in the direction shown by the arrow

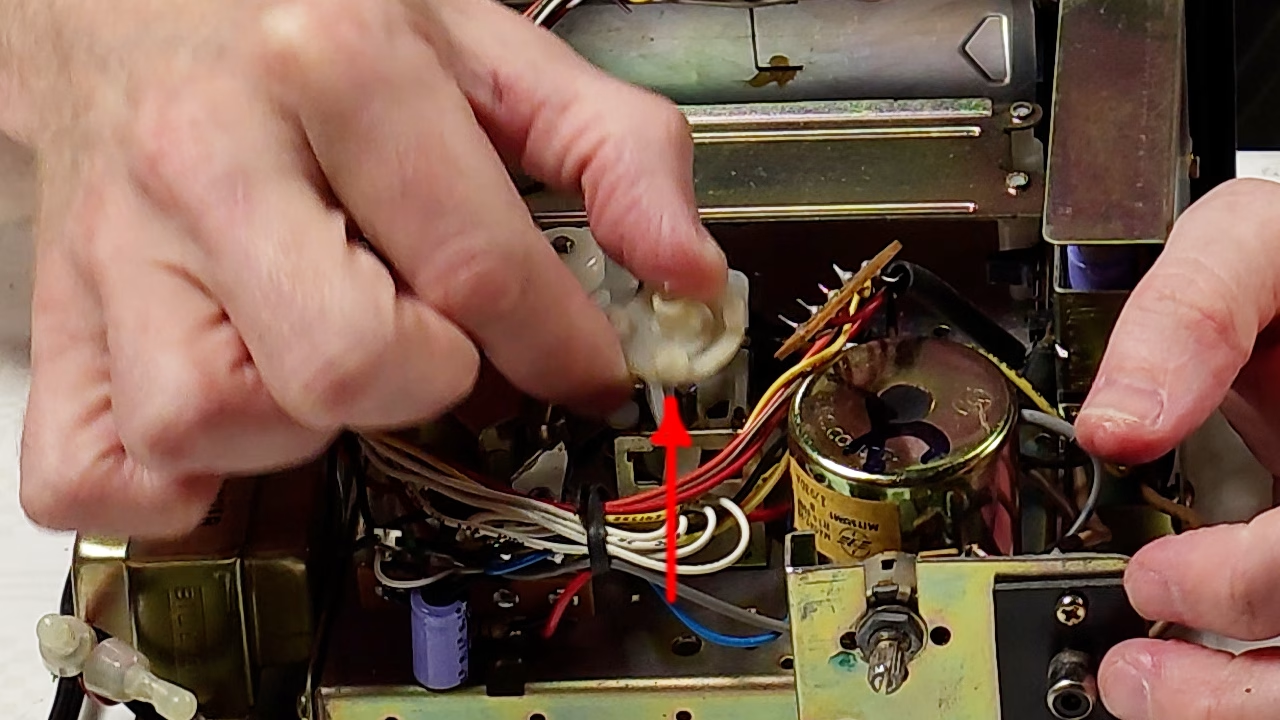

- Lift off the white plastic gear

- Remove the angled white plastic clip and the spring at the bottom

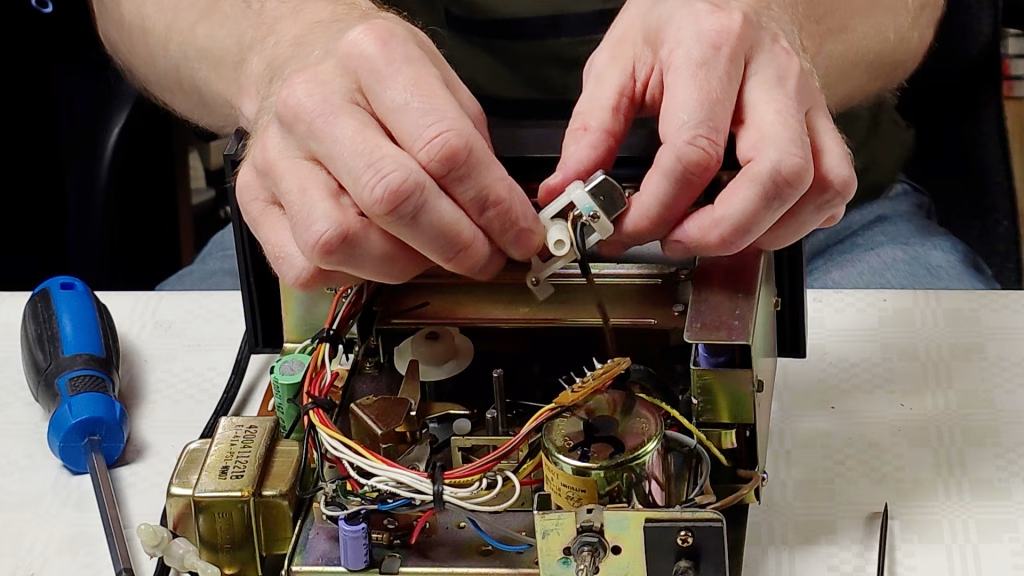

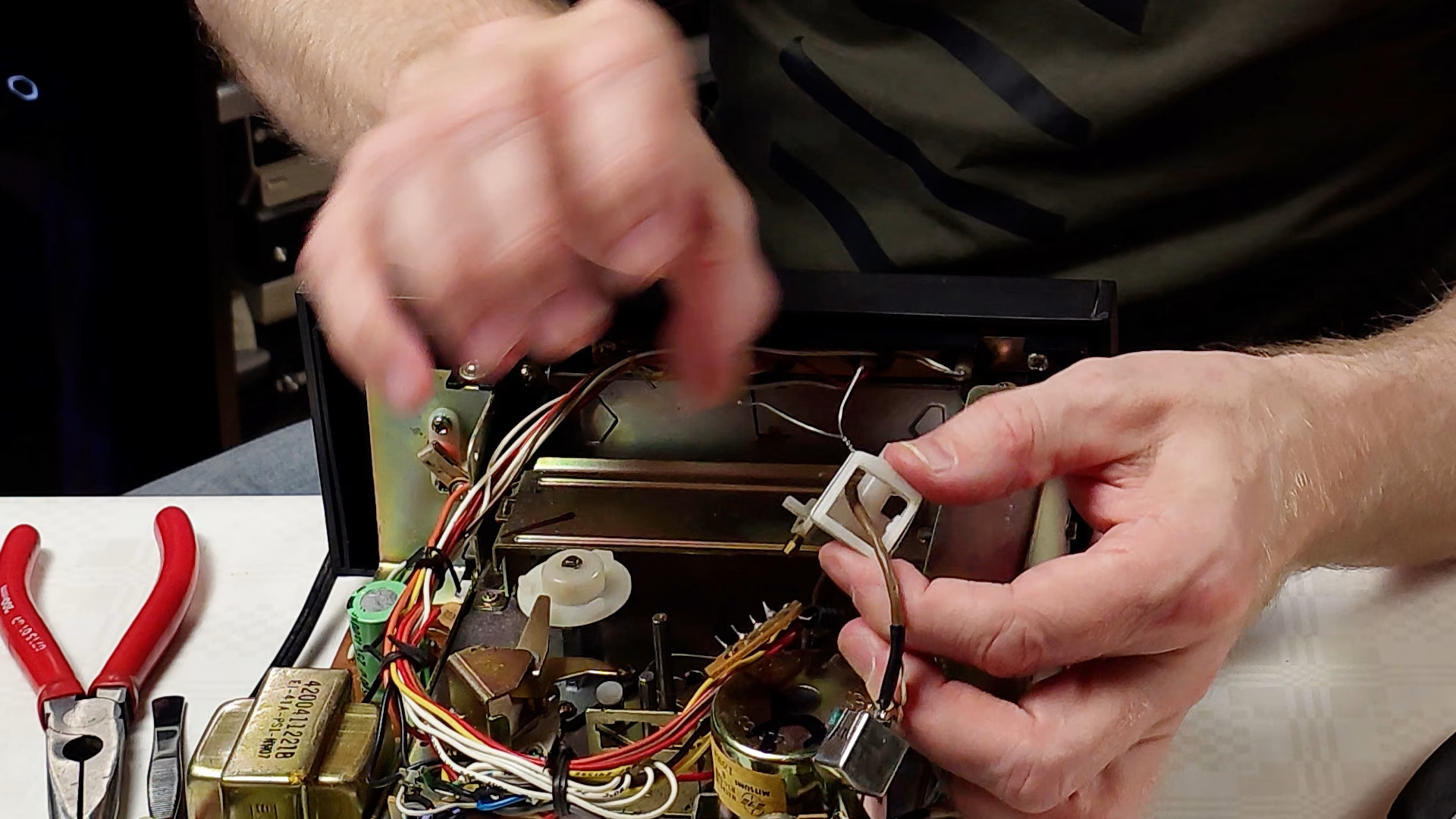

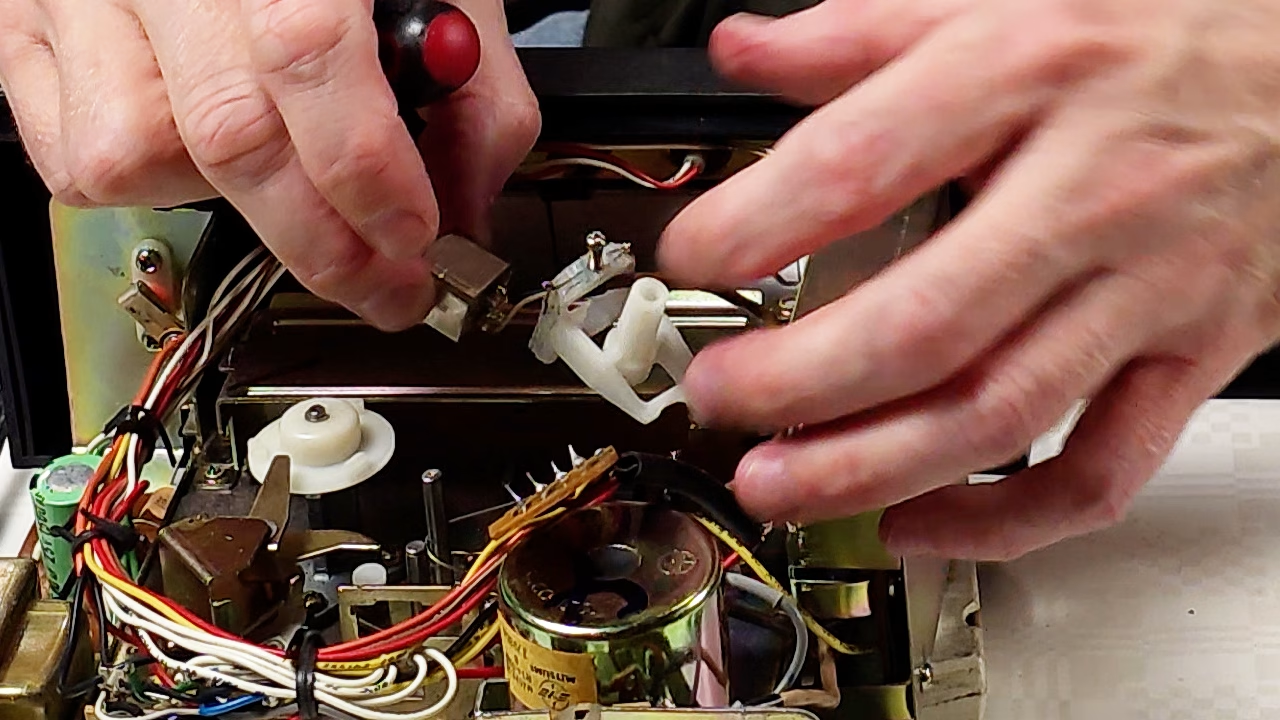

- Carefully remove the entire plastic bracket holding the playback head

- Unscrew the screw securing the sound head and remove the sound head from the bracket.

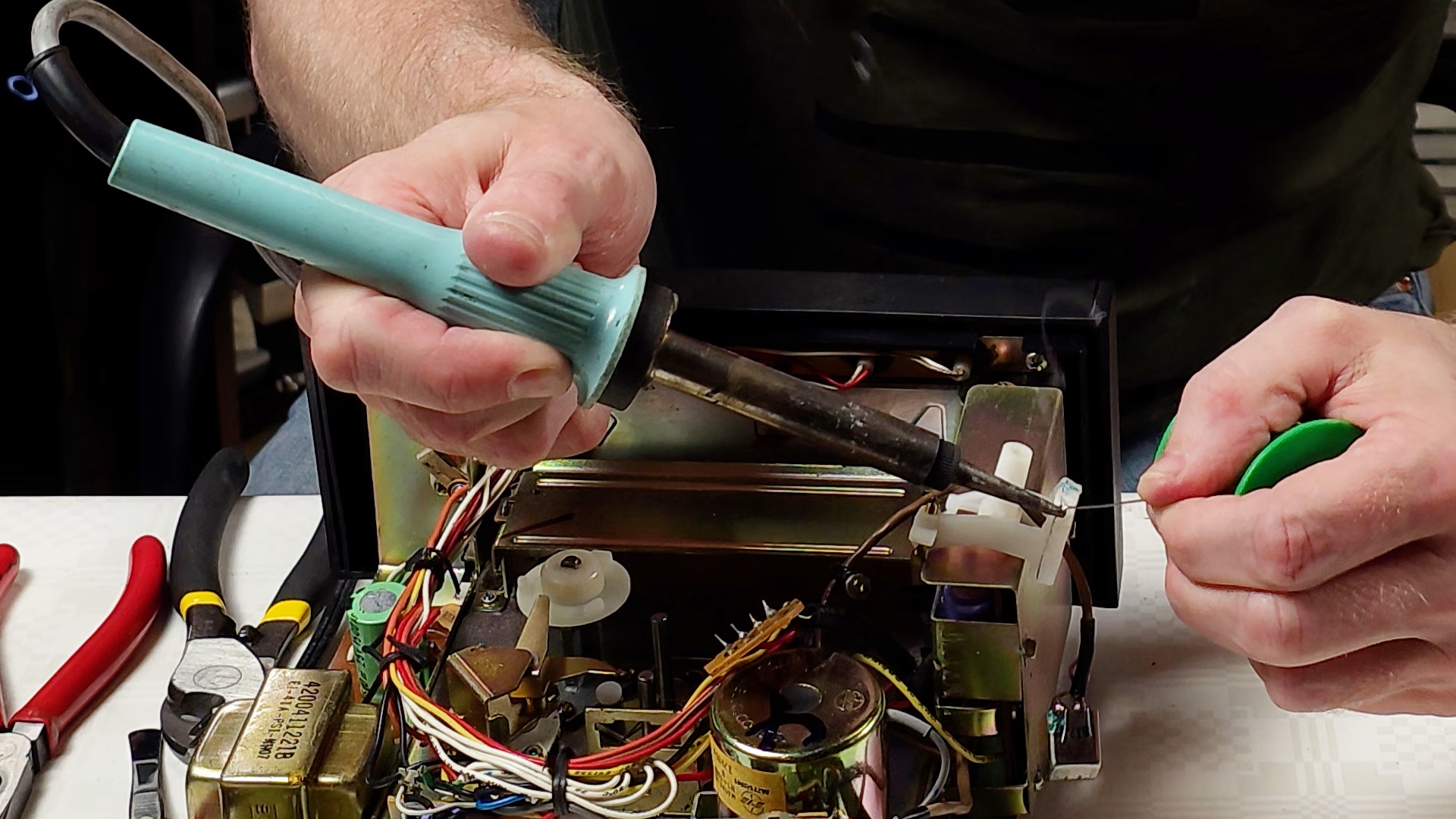

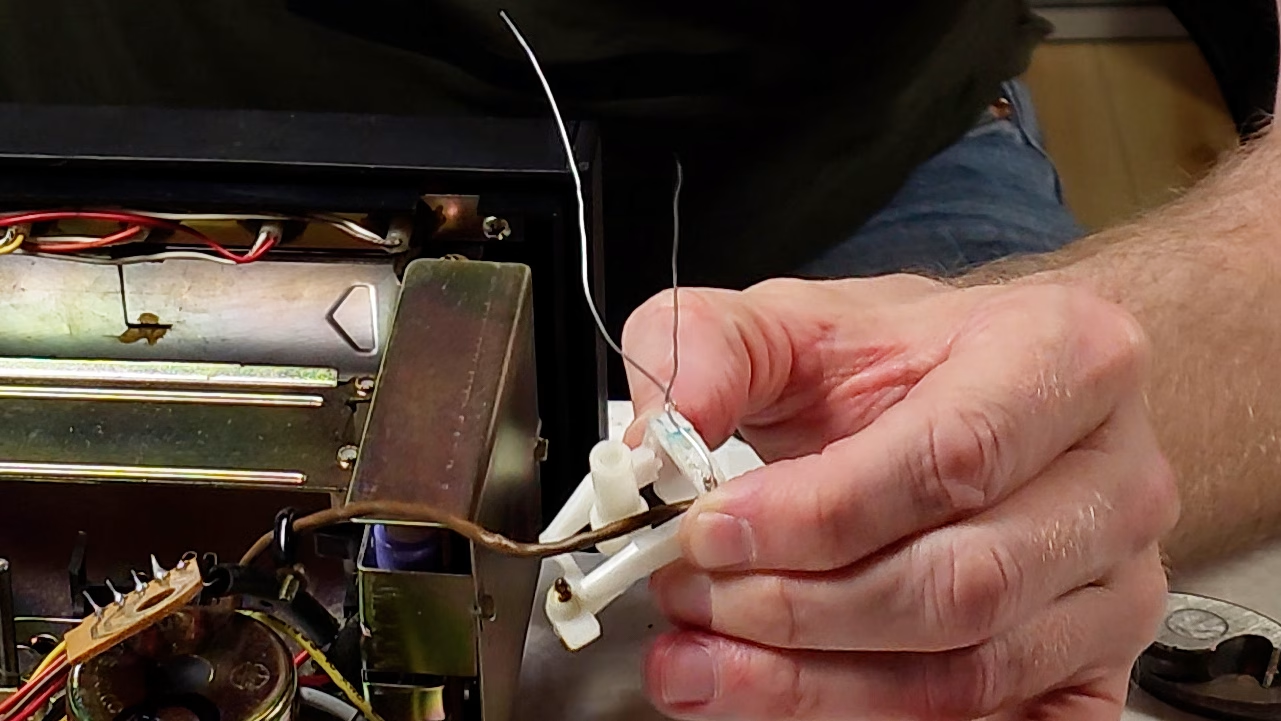

Reinforcement with steel wire:

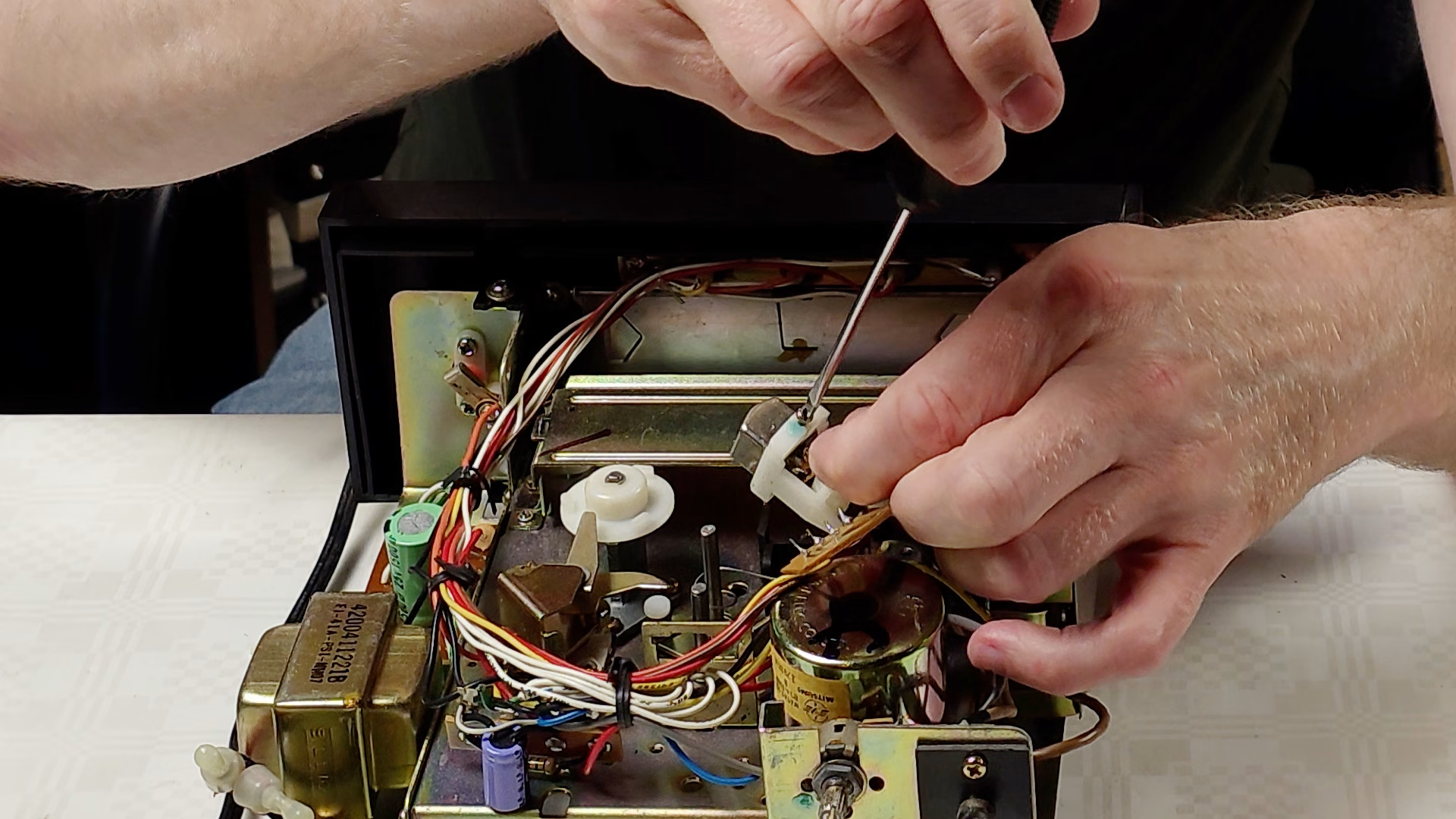

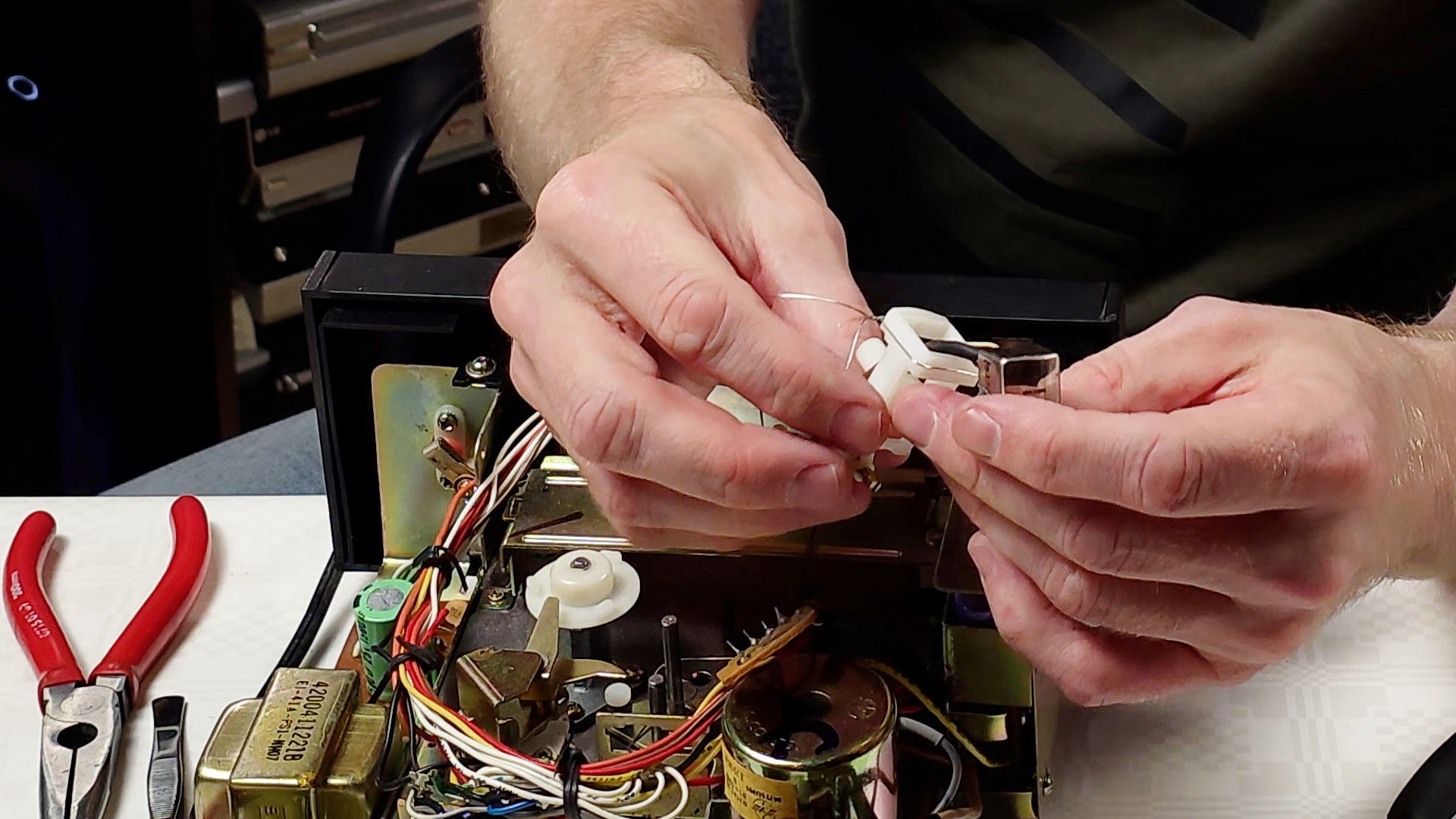

- Wrap a thin steel wire around the plastic bracket and twist it into a “knot” in one corner

- Make sure the wire does not cross the screw hole — it must run alongside it

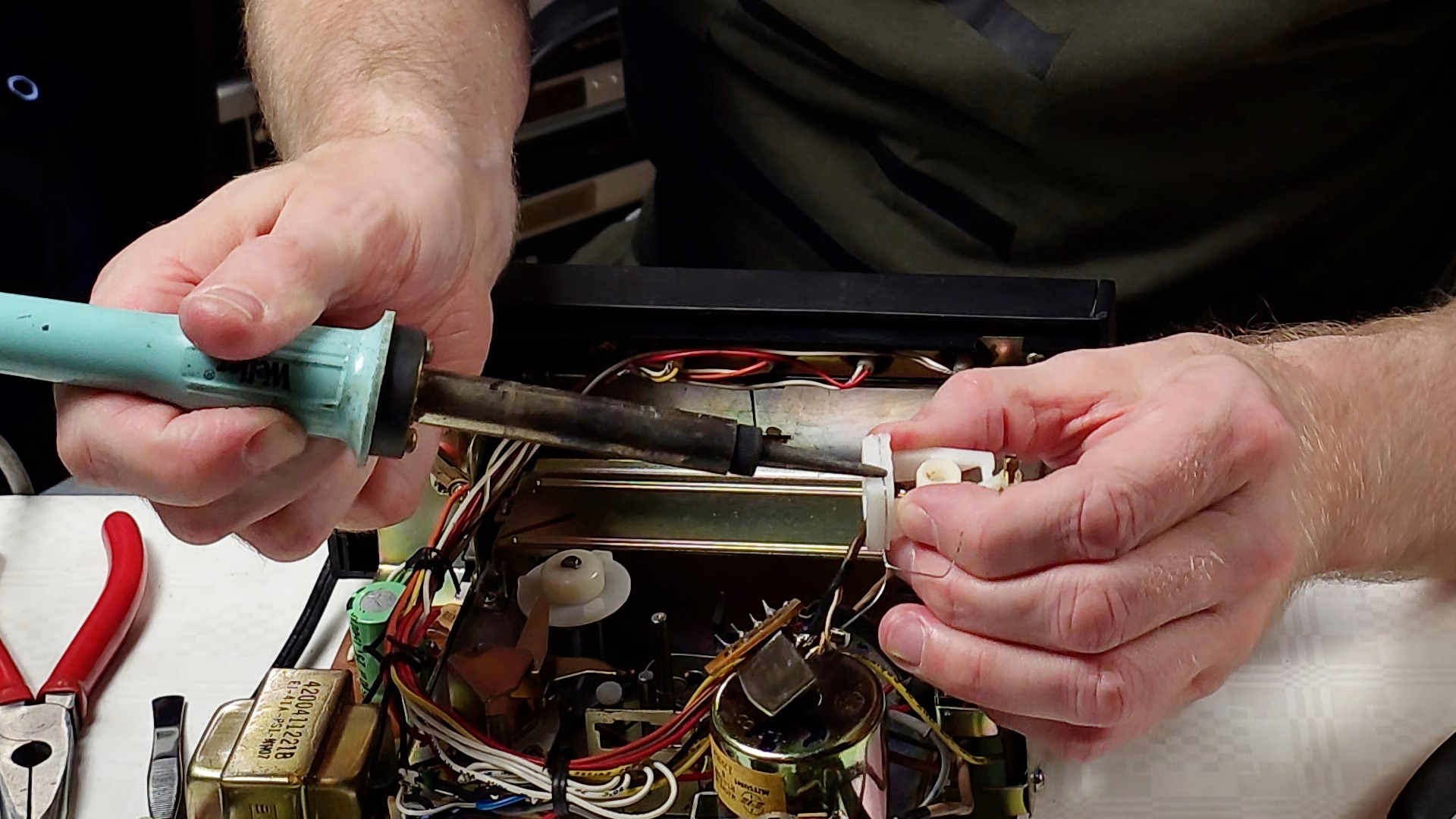

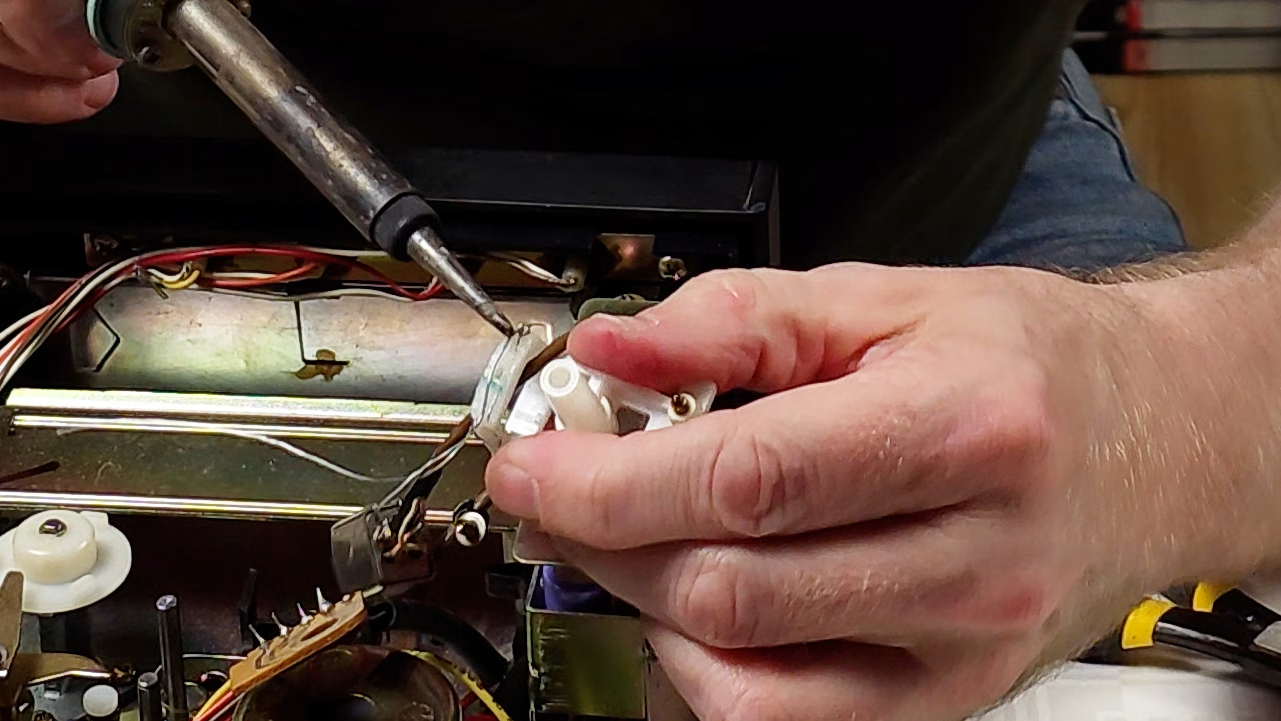

- Use a soldering iron to gently melt the wire into the plastic

- IMPORTANT: Be very careful around the screw hole. Avoid letting the soldering iron deform the plastic, and make sure the wire doesn’t block or interfere with the hole

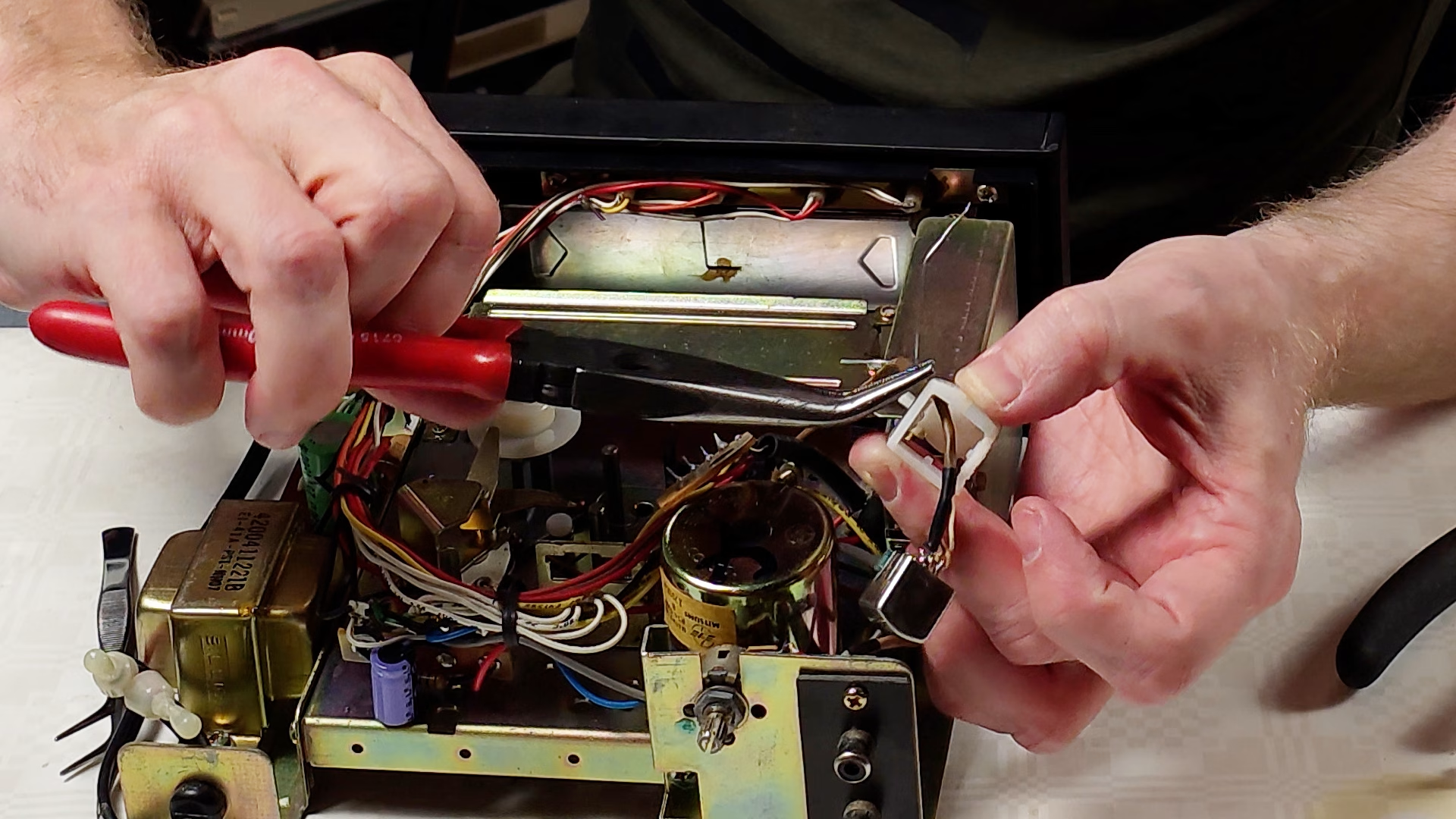

- Tighten the knot with pliers as you go, to keep the wire under tension

- Once in place, add a drop of solder onto the knot to hold it in place

- Repeat the process with a second wire on the opposite side of the screw hole

- Once again: ensure that neither wire crosses over the hole — each should stay on its own side of the hole

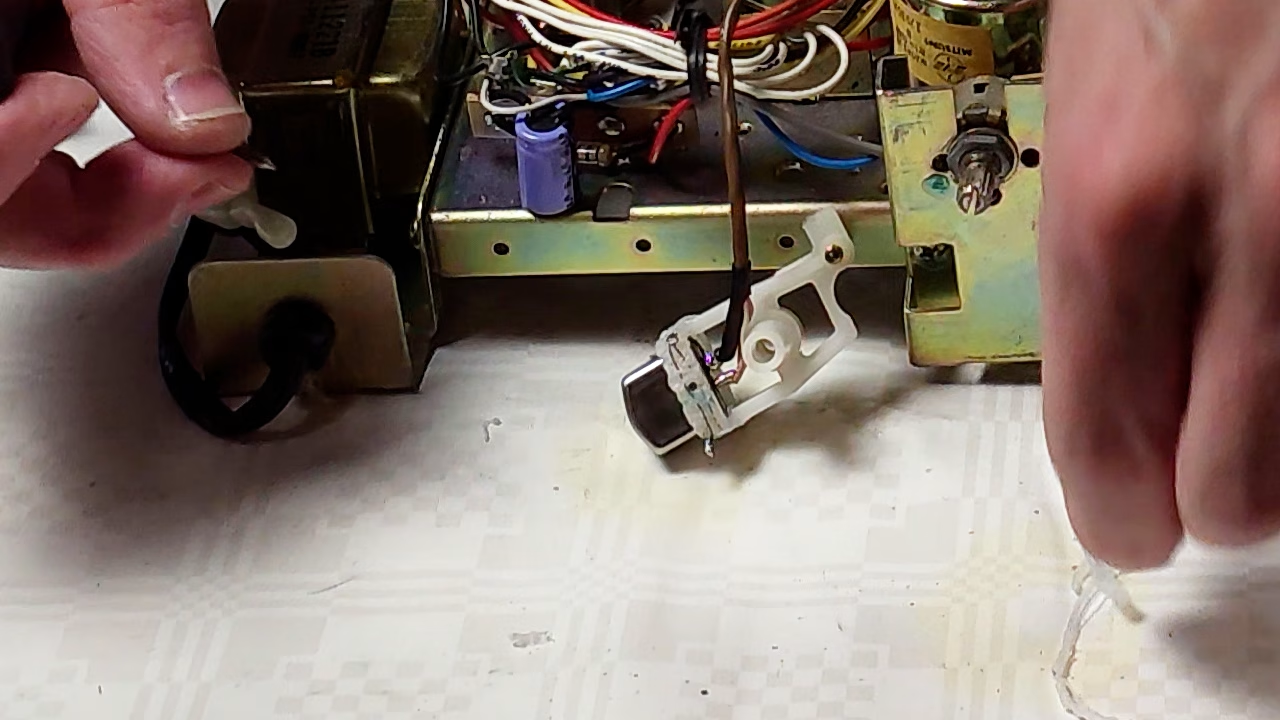

Reassembly and Final Result:

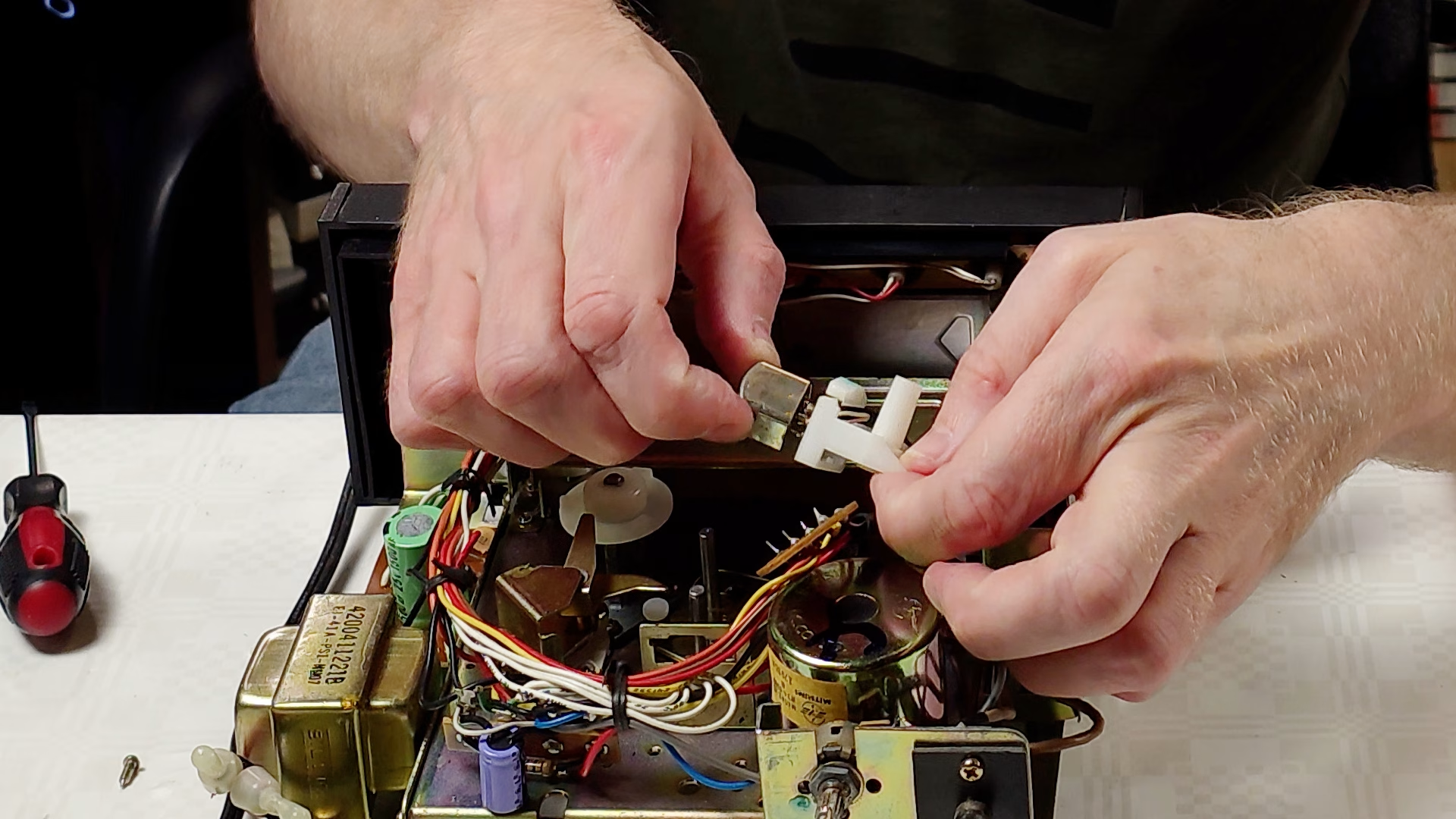

- Reinsert the playback head into the bracket and fasten the screw

- Reassemble the track change mechanism, piece by piece, in the reverse order of disassembly

- The result is a much stronger construction — even more robust than the original bracket was when new